- Description

- Function drawing

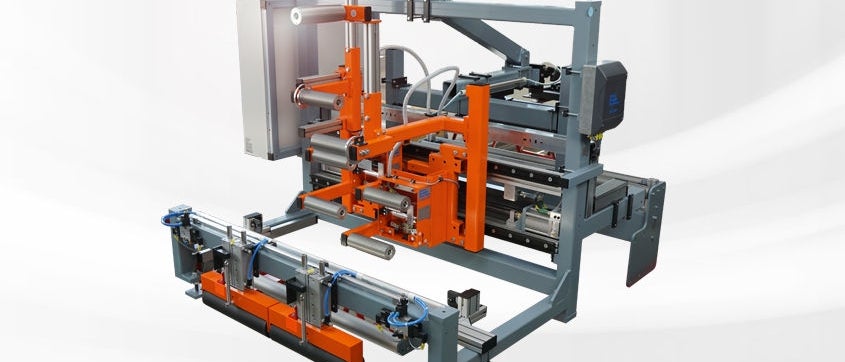

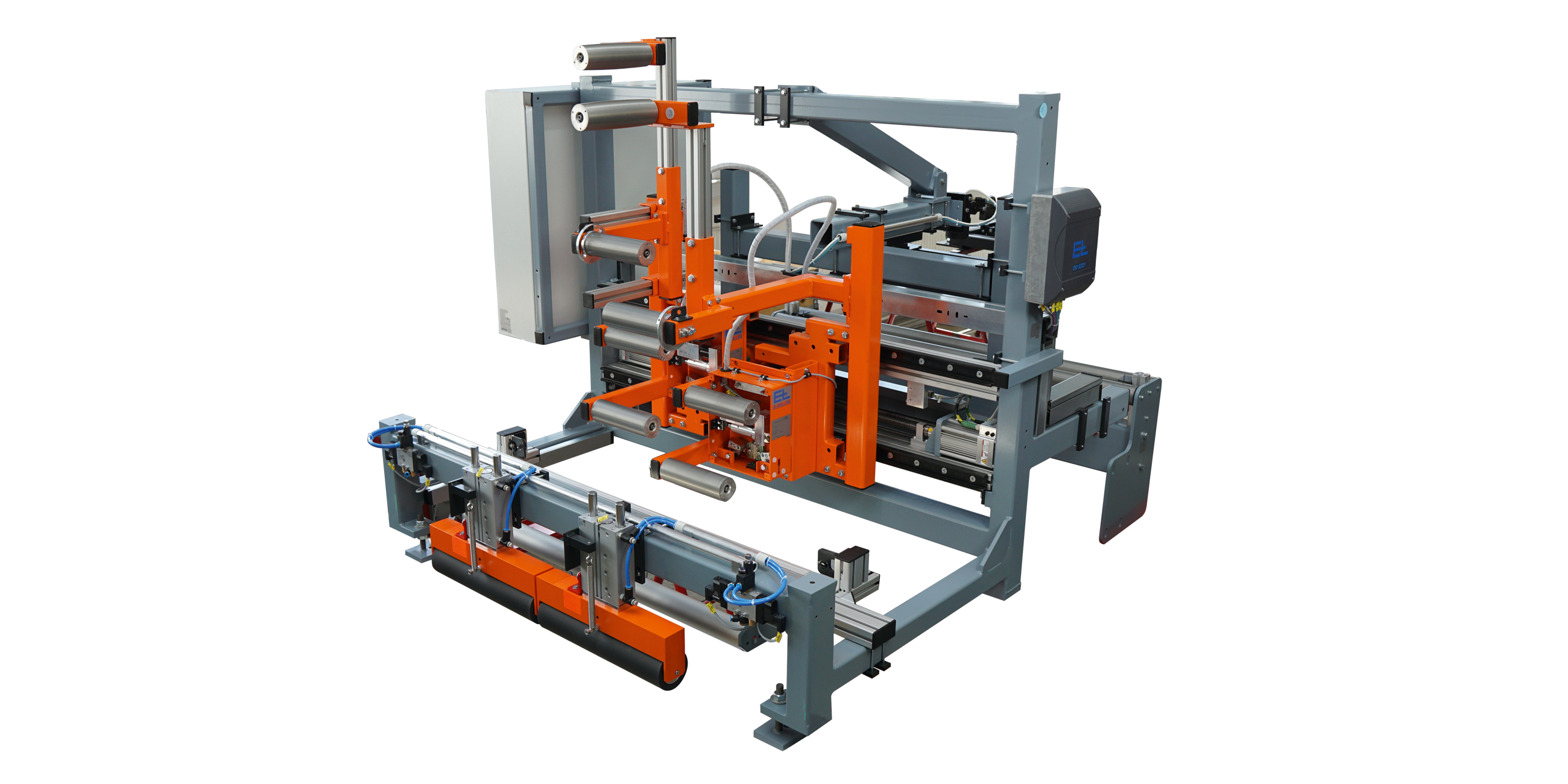

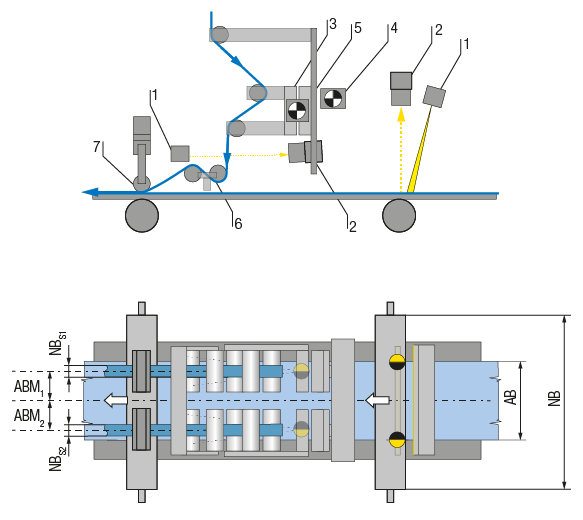

Function

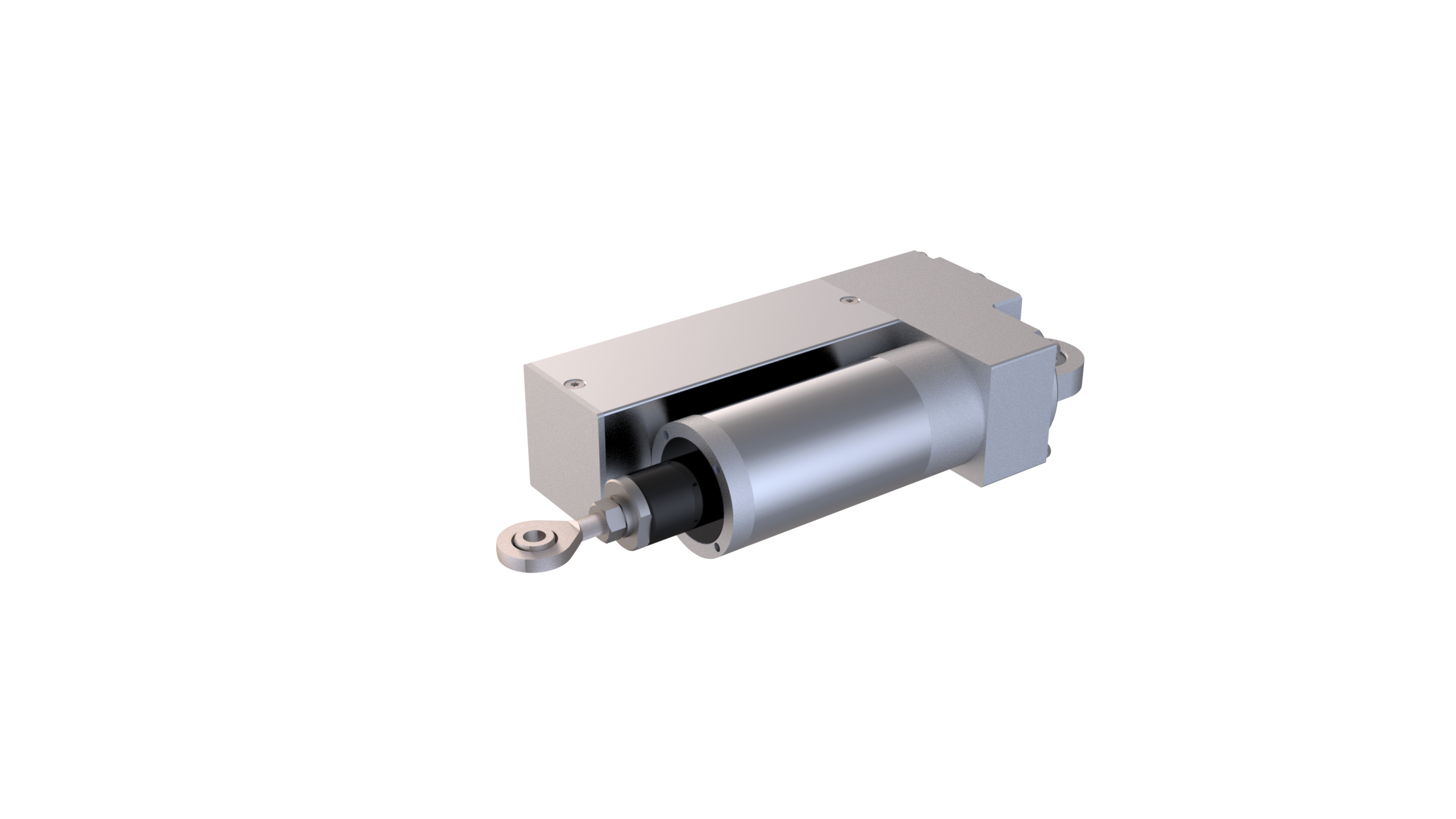

The infeed, the laying in place and the complexing of the pre-cut strips must be extremely exact to ensure precise tire building. CCD cameras or wide band sensors detect the current web position and control digital positioners and actuators. These in turn move pivoting conveyor belts, which enable the required correction of the web or strips.

Area of use

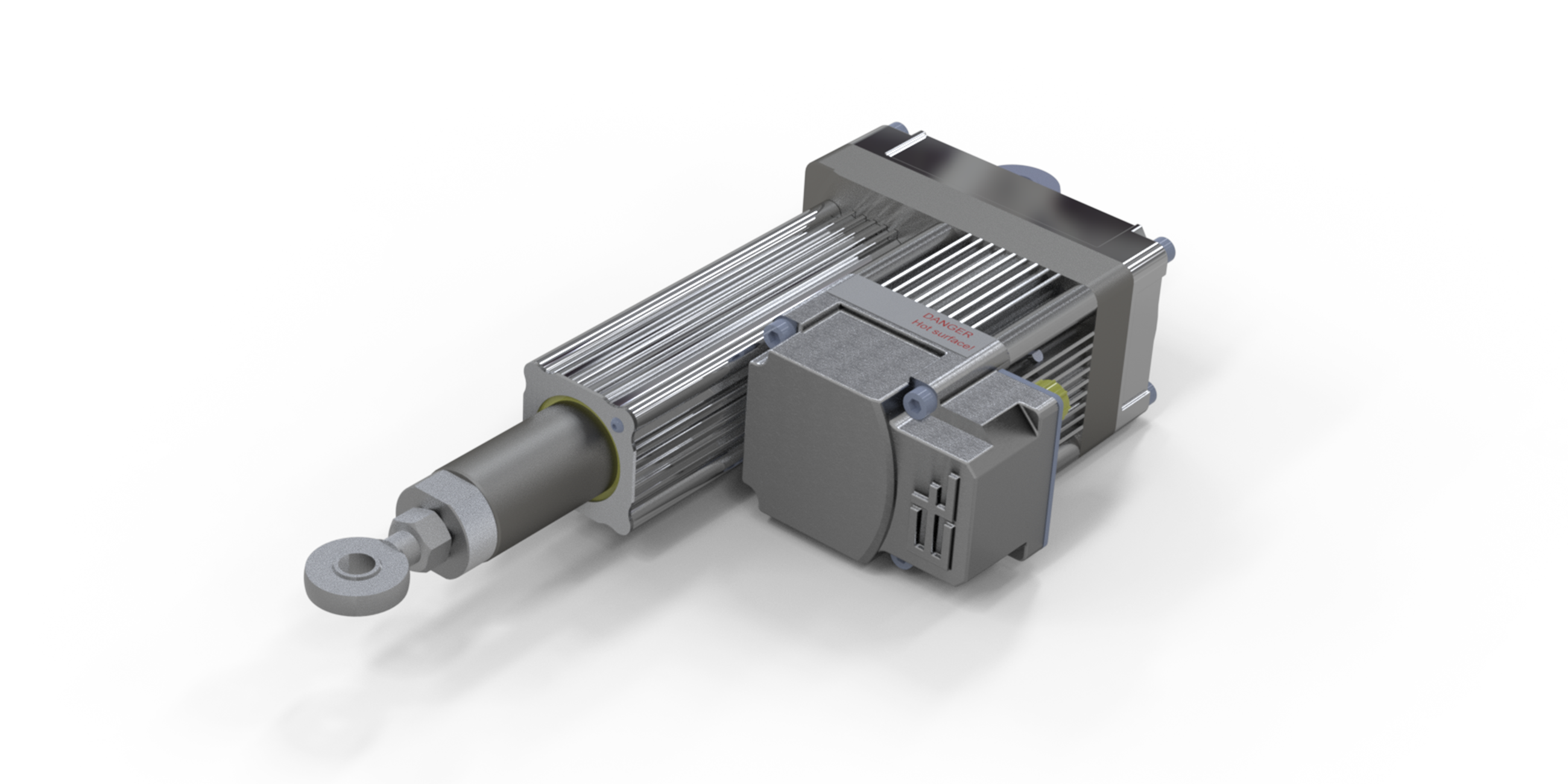

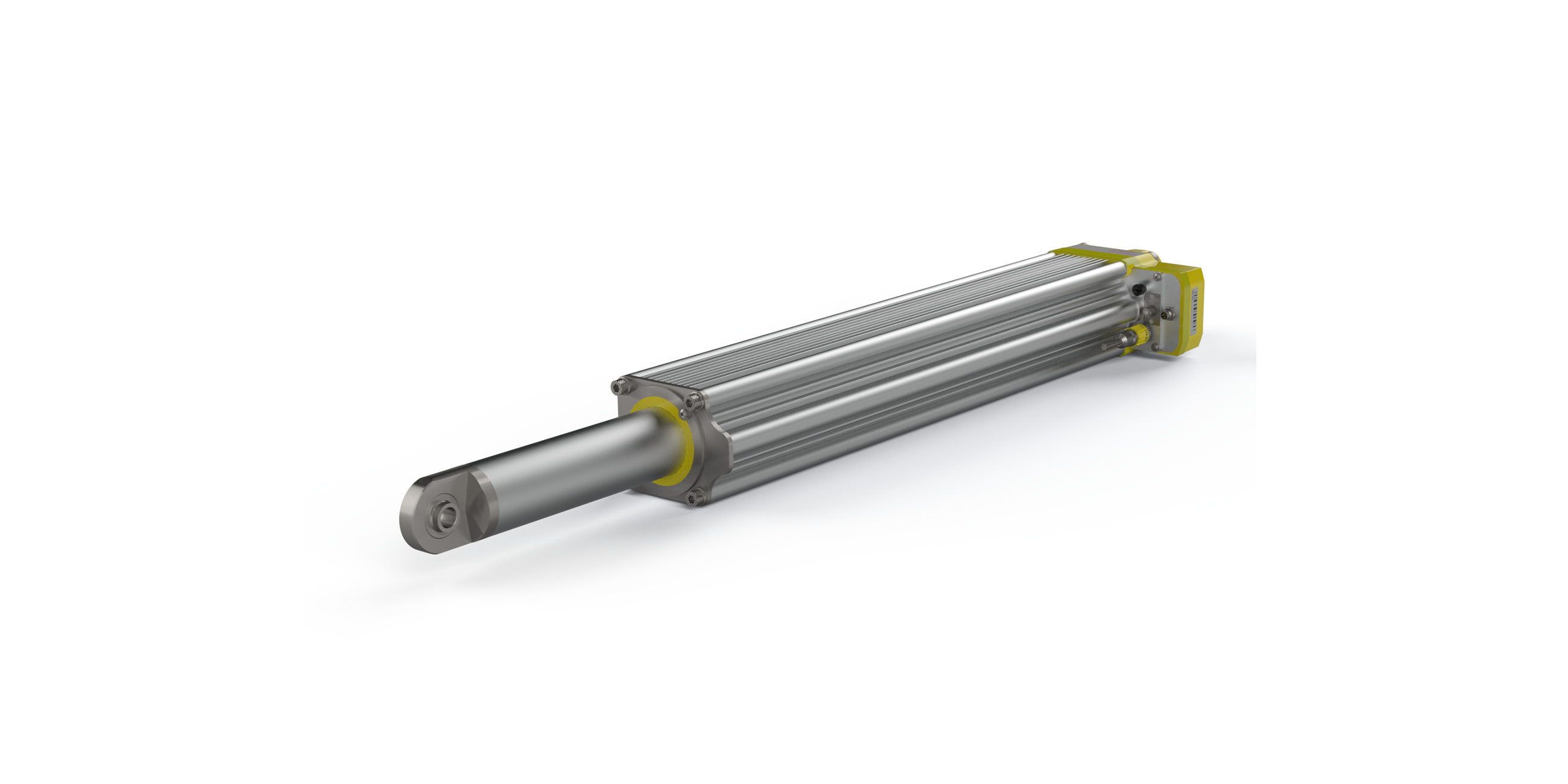

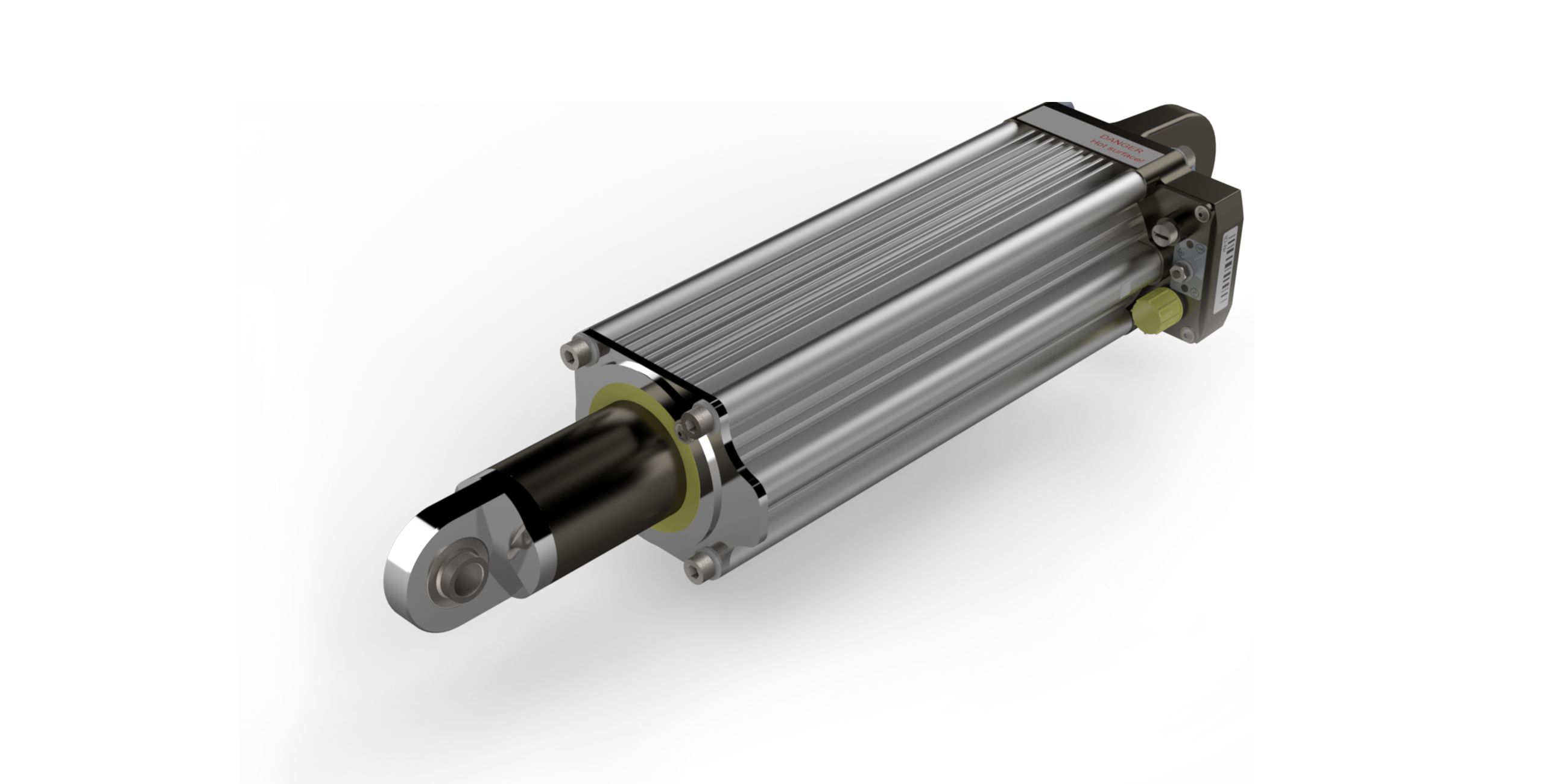

Laminating stations are used wherever rubber webs must be placed precisely on top of each other.

Application

It is to be noted that it is necessary to discuss the requirements in detail before the start of the project. Material width, thickness as well as the state of the material (hot or cold) have an effect on the infeed and the laminating roller. With the aid of all the details, the perfect solution for the related application can be found.

Legend

AB = Operating width | NB = Nominal width | NBS1 = Width, strip 1 | NBS2 = Width, strip 2 | ABM1 = Distance from strip 1 center - web center | ABM2 = Distance from strip 2 center - web center

1 = Light transmitter | 2 = CCD line scan camera | 3 = Web guider | 4 = Support beam | 5 = Actuating drive | 6 = Locking roller | 7 = Pressure roller