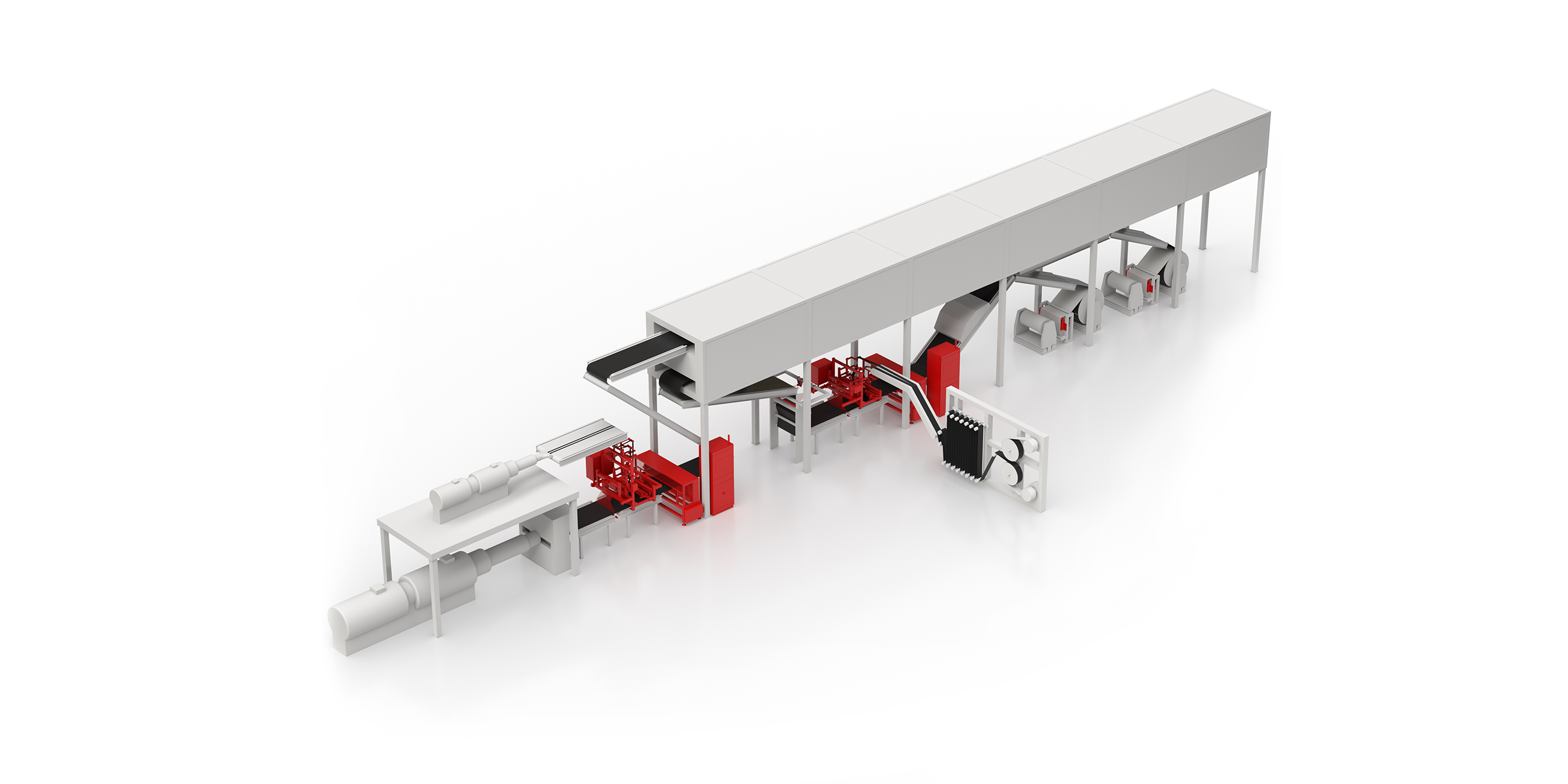

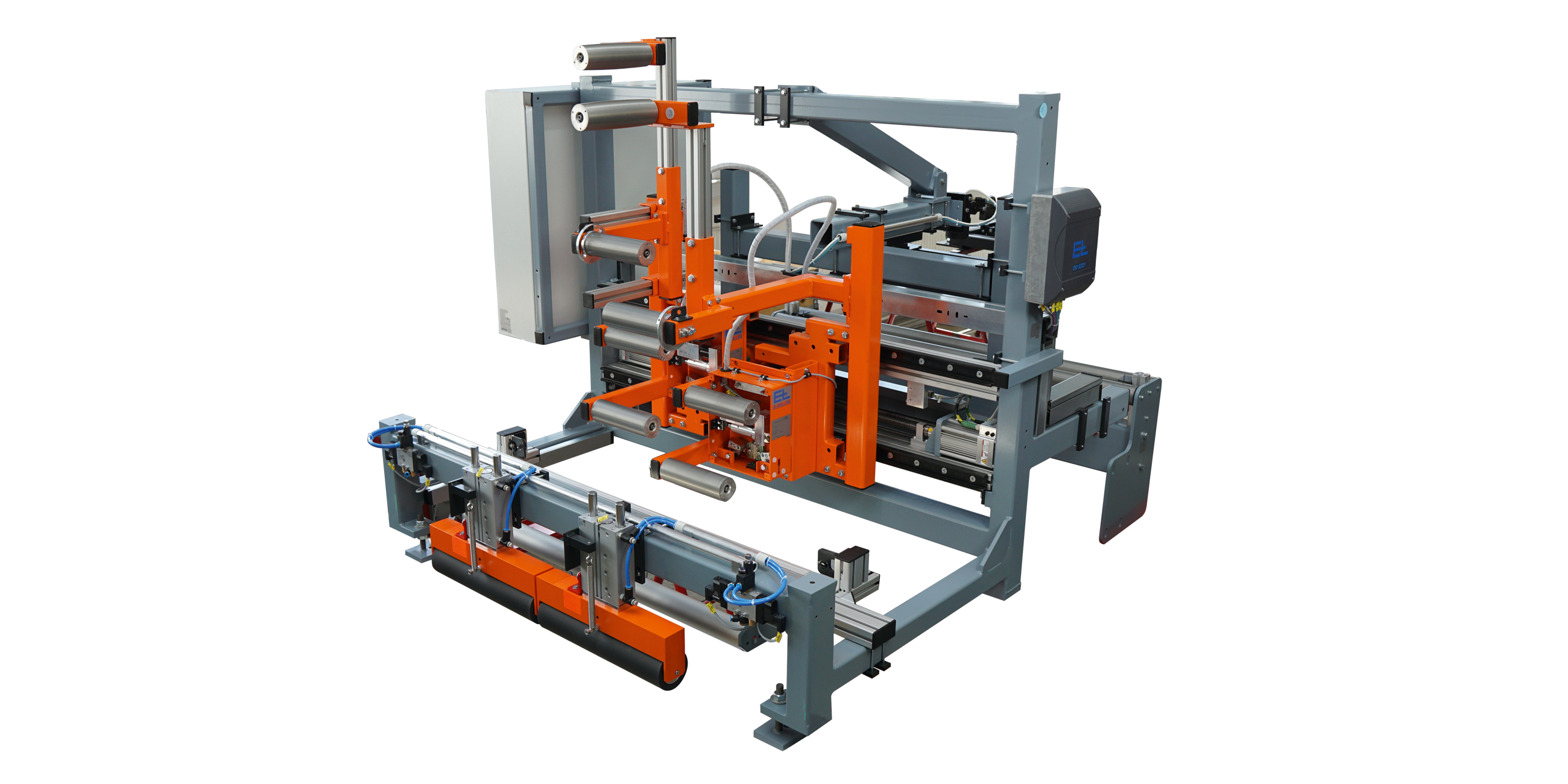

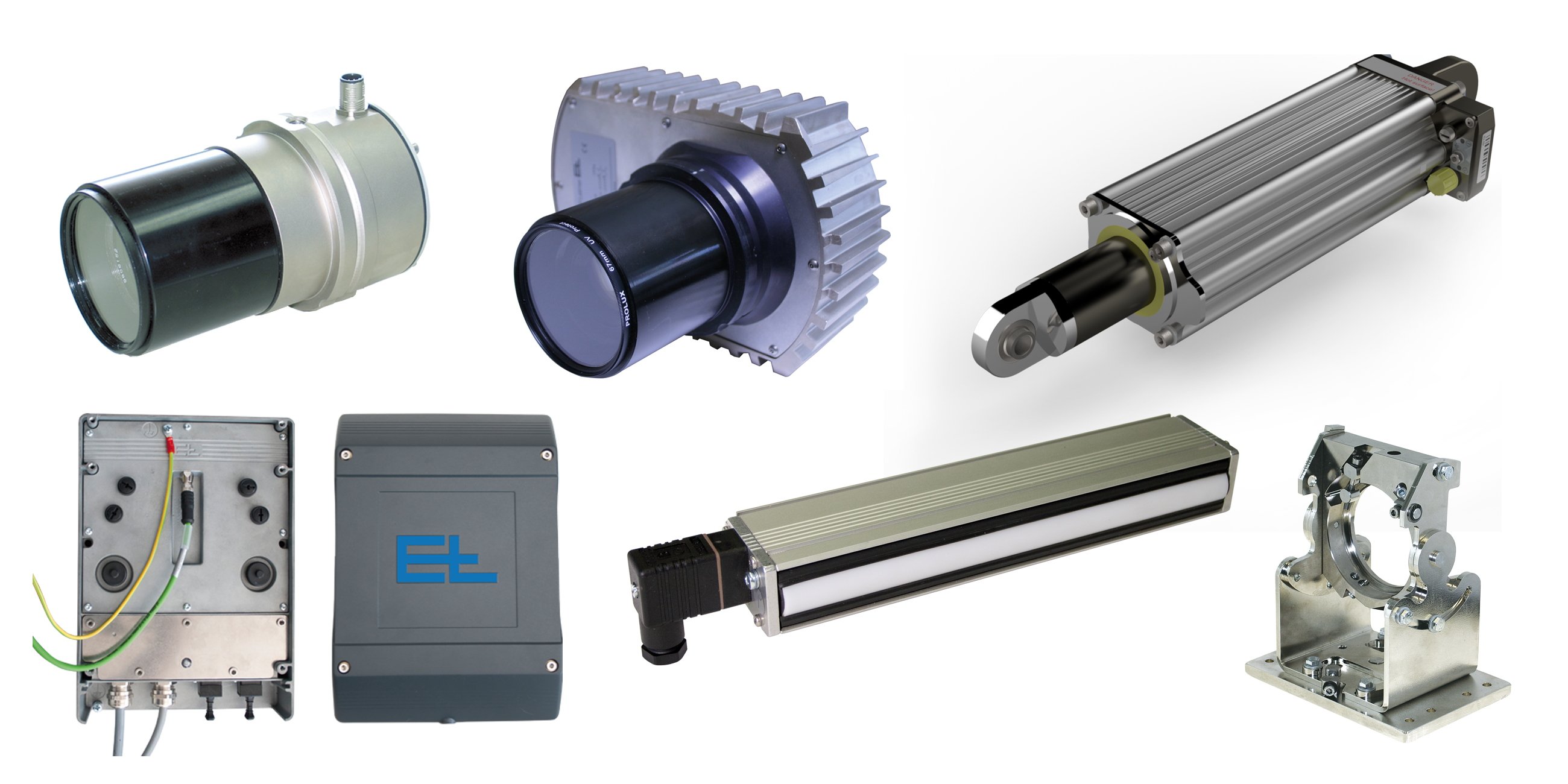

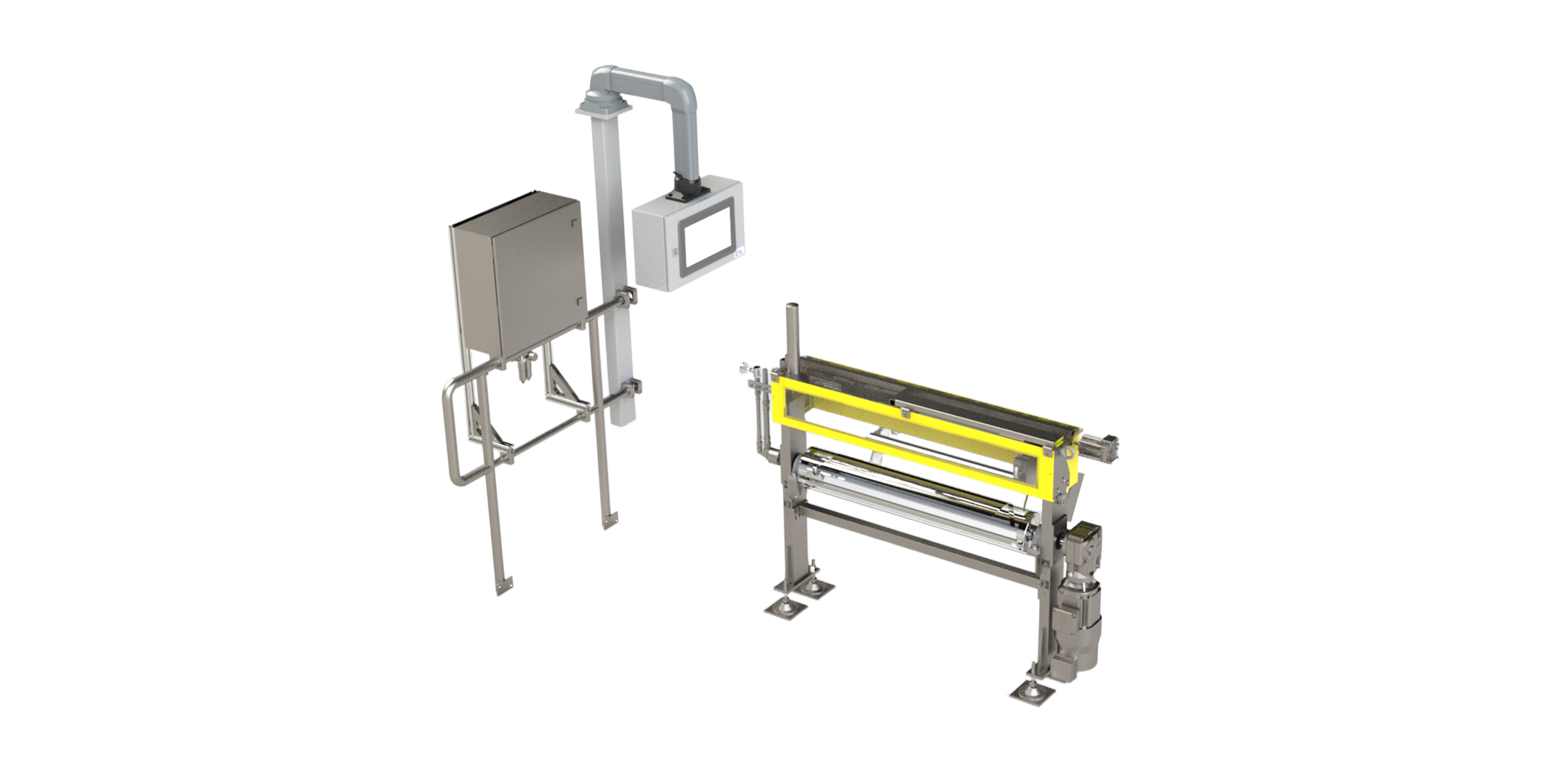

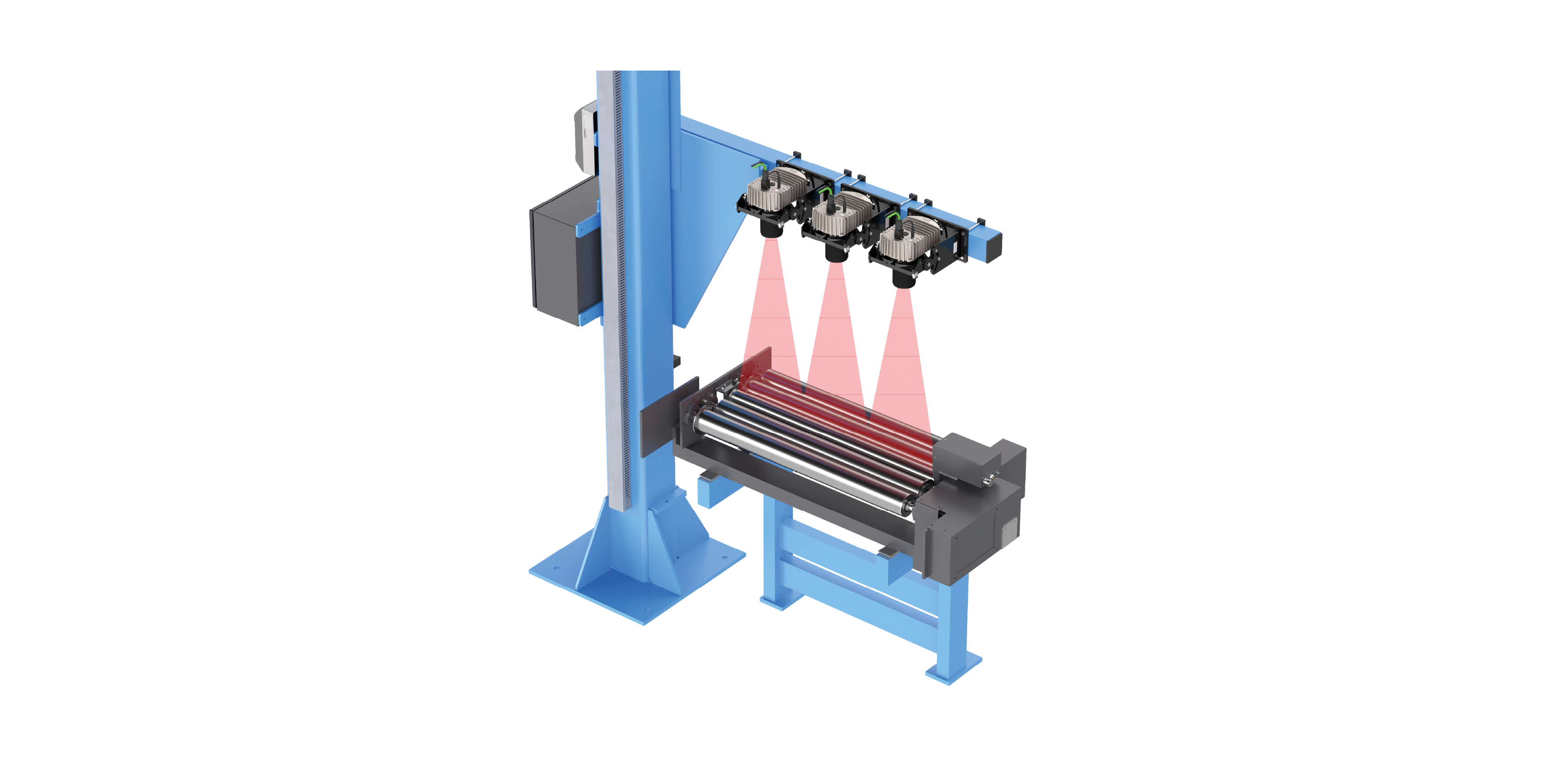

Rubber webs are produced on roller-head lines to form the inner layer of the tire. The inner liner protects the tire from air loss and makes it safe and stable. Our products for control and inspection in roller-head lines, which are specially tailored to the tire industry, meet the demanding requirements of the modern automotive industry and ensure the quality of the end product.